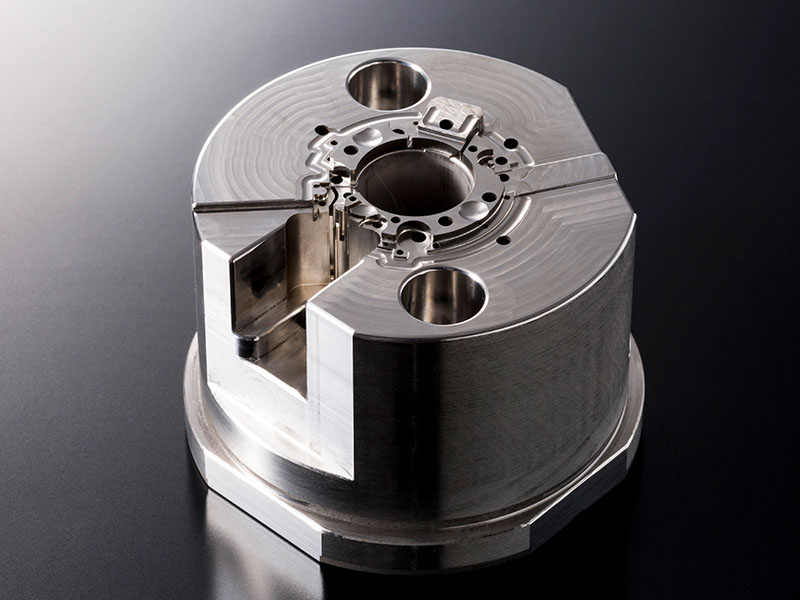

Glass Lens Tooling Forming Moulds and Die Kernels

We are a manufacturer of moulds for the forming of optical components (lenses). Optical lens moulds generally require a very rigorous mirror polishing of the die insert, cavities, cores and inserts.

We support high precision mirror polishing services, not only on carbide materials but also on stainless steel, tool steel and aluminium alloys.

The company is a specialist manufacturer of lens and optical component tooling. We offer precision polishing, five-axis machining, high-speed milling and 3D printing to meet high precision optical component manufacturing requirements.

Manufacture of crystal forming moulds for optical components from drawings

Application of lens forming moulds:

-Lens manufacturing

-Optical tooling

-Automotive

-Aerospace

-Night vision goggles

-Projectors

-Monitors, etc.

Related products

Optical Mould Components and Tooling Inserts

Manufacturer of precision inserts and cavities, we manufacture components such as mould inserts and cavities, die kernels and cores, slides and core pins for the manufacture of optical components from drawings.

Optical Component Mould Insert Manufacturer

Optical component mould insert manufacturer

Die Inserts for Precision Equipment and Optical Components

The company has been specialising in the manufacture of moulded components for 26 years and we are one of the leading brands in the manufacture of moulding tools for the moulding of optical components.

The company uses globally advanced equipment to manufacture mould components, mould cores, mould inserts, mould cavities, mould slides, mould core pins and more.

Optical Mould Components For Car Reflectors Tooling

The finished surface of high precision reflector moulds requires high angular accuracy and a mirror polish. The OEM of precision optical mould components is a successor business to SPP INDUSTRY. The company's technology is also effectively applied in reflector moulds. Mould cores and inserts for 3D curved reflectors such as automotive tail lights are formed by electroforming from a pin-mounted master mould. A tell-tale five-axis milling service and mirror polishing is also available, which can be finished to Ra 0.01µm (slope or flatness)

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.

的模具.jpg)