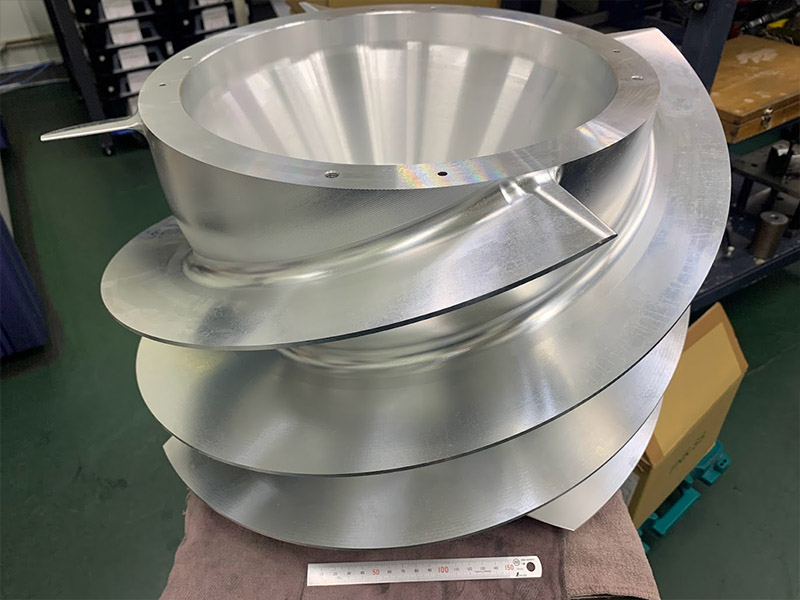

Large Wind Turbine and Impeller Manufacturer

Large wind turbine and impeller manufacture, completed by large five-axis machining.

We offer large scale 4 and 5 axis CNC machining services for milling of large impellers and wind turbines.

Wind turbine and impeller materials are generally used: titanium alloys, aluminium alloys, nickel alloys, high temperature alloys etc.

Manufacture of wind turbines and impellers from drawings

Wind wheels and impellers are generally used in the engine sector.

Related products

Large Crankshaft & Camshaft & Eccentric Shaft Manufacturing

We offer large crankshaft grinding and profile grinding to complete the manufacture of large crankshafts, camshafts, eccentric shafts and other components.

Large CNC Milling Service for Aluminium

We offer large scale CNC machining services for aluminium alloy components, including turning, milling, drilling and thread fabrication.

Aluminium parts are manufactured according to drawings and can also be anodised in various colours and high hardness anodising.

Large Carbide & Hardened steel Rolls Manufacturer

Rolls and roll rings are generally made of tungsten carbide, hardened steel (1.2379/1.2344/SUJ2).

We precision mirror polish our tungsten carbide rolls, which gives the rolls and rings exceptional durability, or we can use tool steel + tungsten carbide coating.

Large CNC Machining

We have 14 years of experience in large CNC machining services, offering CNC gantry milling, planing, vertical turning, boring pins, deep hole drilling, large honing, large cylindrical grinding and more.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.