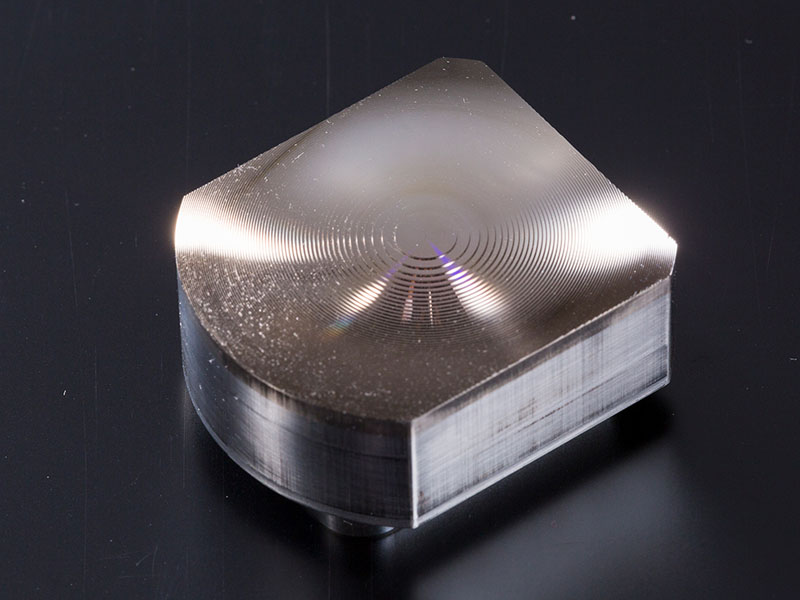

Fresnel Lenses Machining for Optical Tooling Components

Advantages of Precision Machined and Custom Fresnel Lenses and Fresnel Lenses.

Physically, the Fresnel lens has a narrow profile that focuses light similar to a conventional optical lens, but has several advantages over its thicker counterparts:

Light weight: a very interesting option in situations where weight is important (automotive, aerospace, etc.);

Large format: Fresnel lenses are very useful for standard and wide-angle applications;

Various substrate materials: substrate materials vary from acrylic to polycarbonate and glass.

Performance: excellent light gathering capability.

We manufacture Fresnel lens moulded elements according to customer drawings. Due to the lightness of Fresnel lenses, they are used in a wide range of applications in the automotive and aerospace sectors, where they are critical.

Manufacture of optical mould components from drawings

Key areas of category, e.g. automotive, aerospace, etc.

Related products

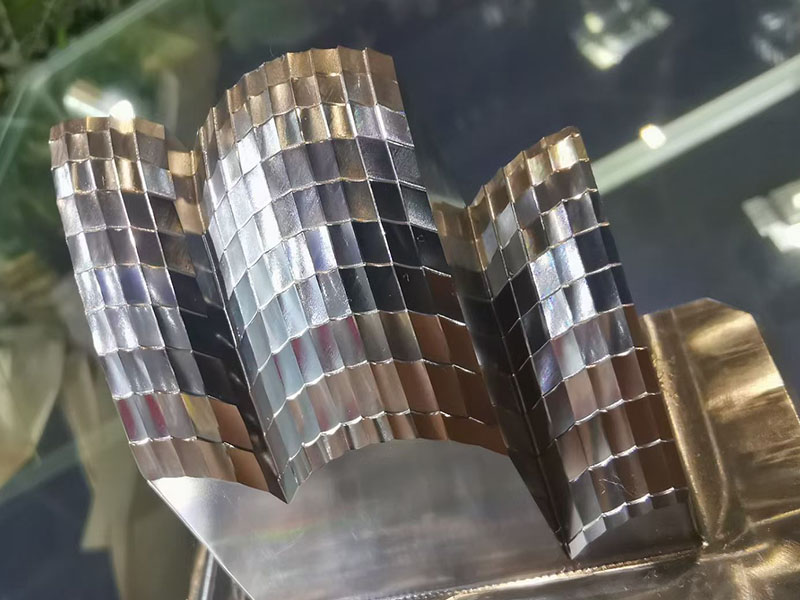

Threaded Core Pins for Optical Tooling Mould Patrs

Manufacturer of threaded core pins for moulded parts for optical components, we manufacture threaded core pins from drawings, the threads are thread ground.

Optical Component Mould Insert Manufacturer

Optical component mould insert manufacturer

Mould Components for Optical Components Manufacturers

The company is very well positioned in the field of moulding tool manufacture for optical components and has become a well-known Chinese manufacturer of optical components and a gold supplier in the field of research.

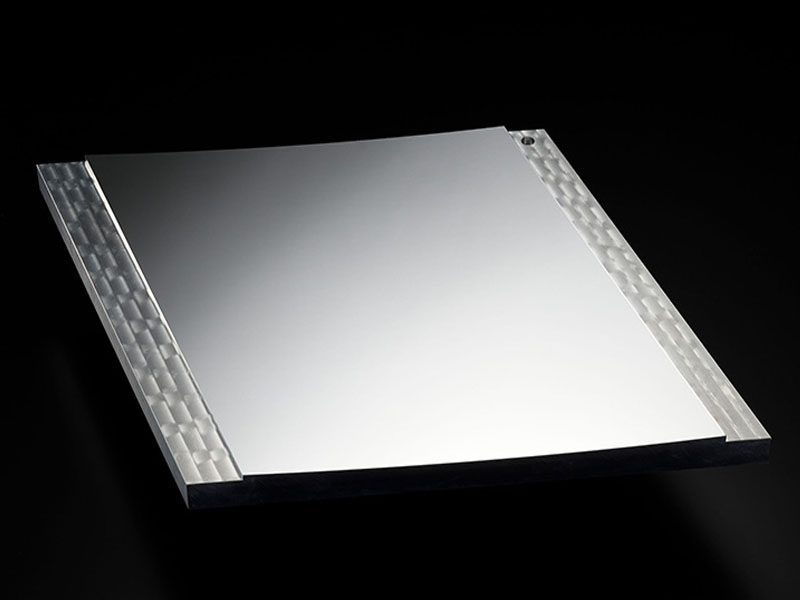

We supply mould components for the forming of optical components including, cores and inserts, slides and die kernels, cavities and cavities, templates and overlay components, punches and matrices.Glass Lens Tooling Forming Moulds and Die Kernels

We are a manufacturer of moulds for the forming of optical components (lenses). Optical lens moulds generally require a very rigorous mirror polishing of the die insert, cavities, cores and inserts.

We support high precision mirror polishing services, not only on carbide materials but also on stainless steel, tool steel and aluminium alloys.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.

的模具.jpg)