Injection Moulding for Sophisticated Plastic Optical Components

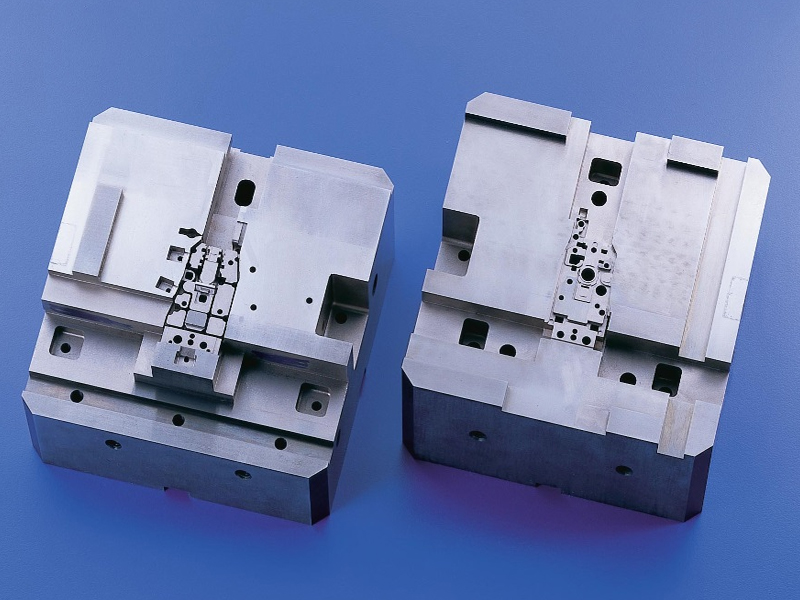

We supply mould components for the optical sector, including injection moulding tools and moulds, microfluidic components, silicone optical injection mould components, mould components for optical components for automotive headlamps, sensor optical mould cores and inserts, cavities and core pins for micro-optical moulds for camera systems, mould punches and bushings for LED lighting systems, etc.

Material: 1.2343/1.2344/HSS/SKD11/SHH51/M42/M2/ASP23/Tungsten Carbide/Technical Ceramics/Beryllium Copper etc.

Precision injection moulded components for the optical sector are subject to very precise machining processes and we offer high precision CNC machining, grinding, WEDM and EDM, turning and milling, drilling, micro fabrication and much more.

Manufacture of optical mould components from drawings

Application areas for optical mould components:

-Optical lenses

-Glass forming

-Injection mould inserts

-LED lighting

-Microlenses

-Polymer lenses

-Life science and medical technology

-Automotive

-Injected silicon arrays etc.

Related products

Die Inserts for Precision Equipment and Optical Components

The company has been specialising in the manufacture of moulded components for 26 years and we are one of the leading brands in the manufacture of moulding tools for the moulding of optical components.

The company uses globally advanced equipment to manufacture mould components, mould cores, mould inserts, mould cavities, mould slides, mould core pins and more.

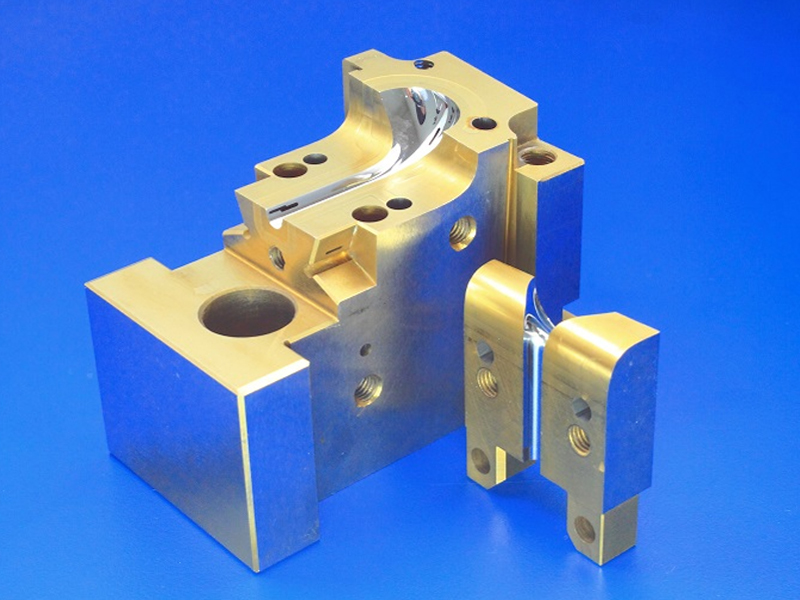

Automotive Lens & Mirror Forming Die Tooling and Parts

The company has 16 years of experience in the manufacture of moulded components for automotive lenses and lens moulding. We manufacture moulded components and tools for optical components, which consist of tungsten carbide or hardened tool steel with a rigorous mirror finish.

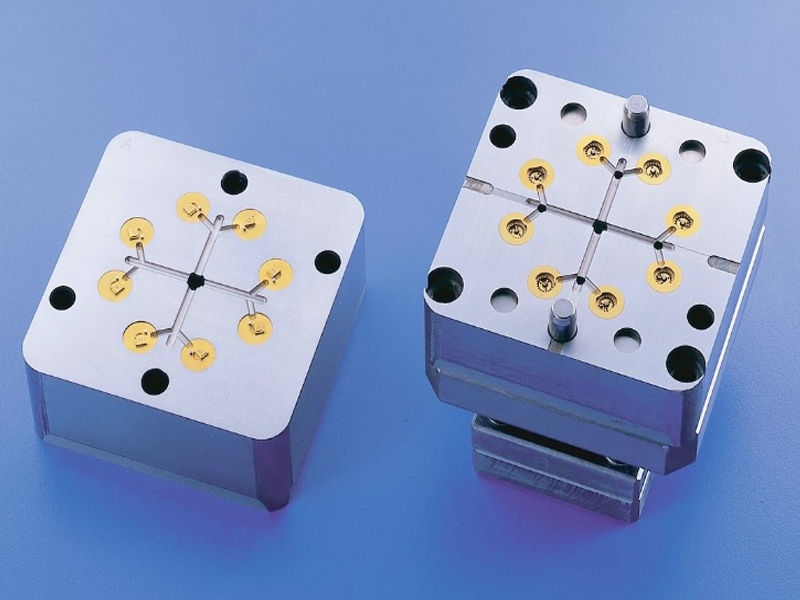

IC Package Mold Parts Cavities and Inserts

We offer fabrication and customization services for semiconductor die components, including:

-IC encapsulation die cavities and inserts

-IC leadframe stamping die punches and bushings

-Semiconductor packaging die plungers and pots, -Semiconductor packaging die plungers and pots

-Encapsulation die cores and core pinsMaterials: tungsten carbide, technical ceramics, tool steel, HSS, ASP23, etc.

Sinker EDM & Wire EDM Service Manufacturers

We offer Sinker EDM & Wire EDM services, manufacturing:

-Precision terminal connector mould components-

-Semiconductor mould components

-Injection mould components

-Internal spline components

-Automotive engine cylinders

-Motor core mould components

-Gear and gearbox components

-Electronic components (sensors, microchips)

-Turbine blades, landing gear components and wheel blades

-Medical implants etc.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.