Semiconductor Pot & Carbide Plunger Manufacturers

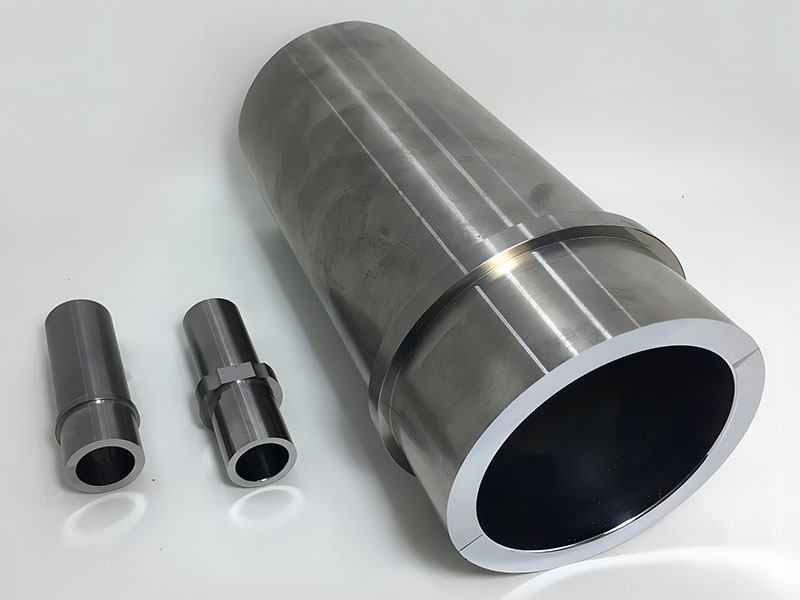

The company is a manufacturer of the semiconductor Pot & Plunger, which is finished in tungsten carbide and is manufactured and customised according to drawings

Tungsten carbide Pot & Plunger for semiconductor packaging moulds, and multi-cavity moulds. Our Pot & Plunger is finished with tungsten carbide or M42 high speed steel to achieve superb ease of use and wear resistance, feel free to test our Pot & Plunger.

Manufacture of tungsten carbide Pot & Plunger for semiconductor packaging moulds from drawings

Applications of the semiconductor Pot & Plunger:

Manufacture of semiconductor packaging moulds

Related products

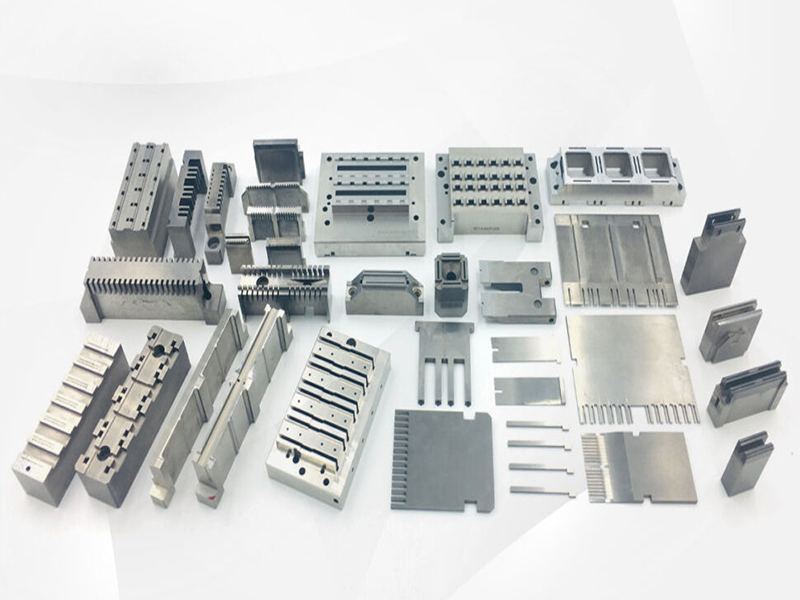

Auto Mold & Chase and Conversion Kit

Automold Chase

-All kinds of automold chases

-All kinds of full conversion kits for auto mold system

-Solution for venting and gating design to ensure good moldability performance (Void, Wire Sweep and incomplete filling)

-Standard Cavity Bar Material : ASP23

-Convertible Mold Die for other package type

-Minimized compound usage Automold Conversion Kits

-All kinds of full conversion kits for auto molding system

Semiconductor Components and Tooling Manufacturer

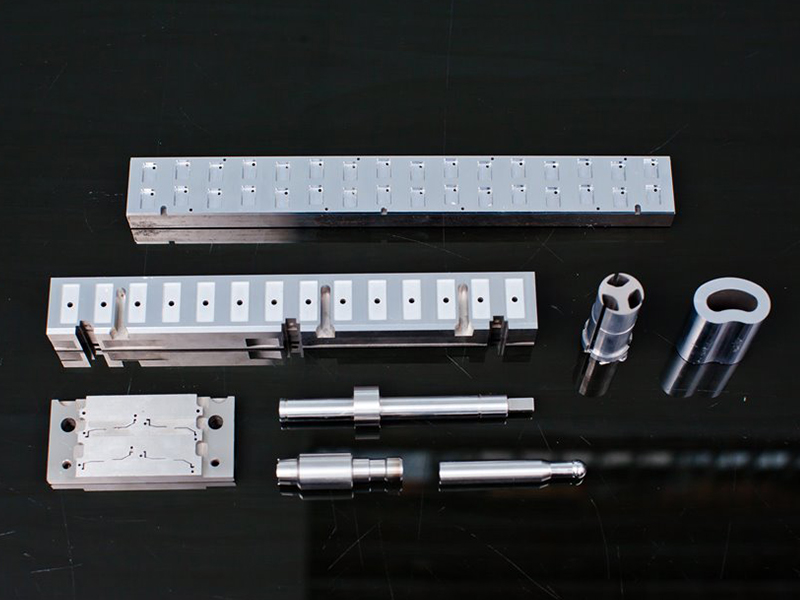

We are a manufacturer of semiconductor components and tooling, providing high precision OEM parts services, including tungsten carbide punches, package mold cartridges and plungers, leadframe stamping mold parts, IC hot runner gate parts, etc.

Semiconductor Leadframe Tooling Stamping Punches

Many different types of leadframes are used in semiconductor devices, and SPP INDUSTRY designs and manufactures molds, assembles stamping dies, and mass produces and supplies a variety of high precision and quality leadframes and stamping die components.

Custom Machining Pot & Plunger for Semiconductor Packaging

The company is one of the largest manufacturers of Pot & Plunger in China and we provide OEM services for Pot & Plunger to well-known semiconductor companies in China and Taiwan.

Pot & Plunger is used in the manufacture of semiconductor packaging moulds. The company's Pot & Plunger can be manufactured using M42 high speed steel or tungsten carbide and can also be supplied with additional PVD coating services.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.