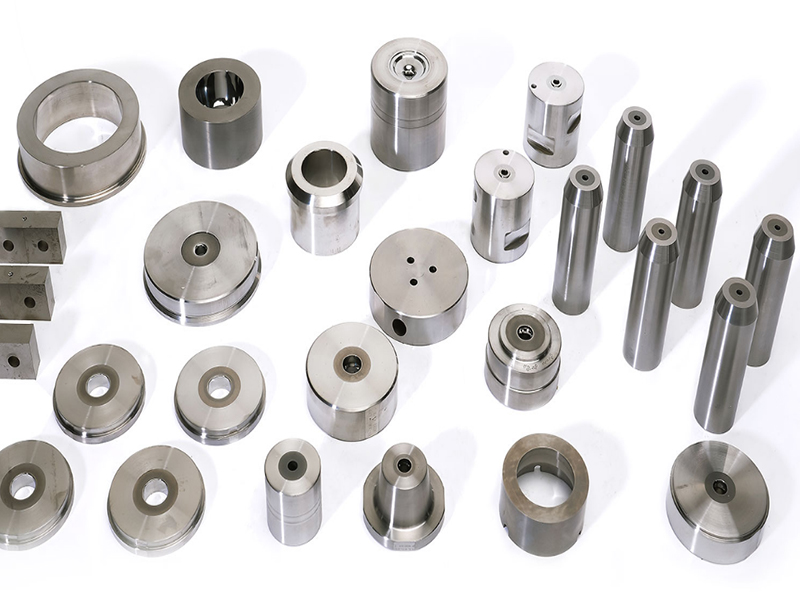

Aerospace Cold Heading & Forging Tooling

Aerospace

The aerospace industry is perhaps the most demanding and demanding of the industrial sectors.

SPP CNC MACHINING's expertise in part customization, accuracy, durability and speed to market are the main challenges aerospace manufacturers face in today's market. Due to the high demand for customized parts in unique alloys such as Inconel, Hastelloy, Tungsten Carbide, Technical Ceramics, Vaspaloy or Titanium, aerospace manufacturers need machining partners that can meet the demands of these alloys and have the expertise and know-how to produce the right part for the right aerospace application.

SPP CARBIDE offers unrivaled materials and machining process knowledge

SPP CARBIDE understands the unique challenges our customers face in forming these specialized materials. We work with our customers to ensure that the best possible materials and machining processes are used in the manufacture of cold or hot formed molds.

Our part machining services and solutions are used by aerospace companies for a number of custom tool and die components, including:

-Steel and carbide die inserts

-Hexes and twelve-points

-Carbide torx pins

-Punches

-Segmented hexes

-Segmented twelve-points

-Power dies

-Tungsten Carbide Dies

-Carbide wear parts

-Carbide cold forming tooling

-Carbide hot forming tooling

-Dressing Dies

-Shaping dies

etc.

Manufactures cold and hot forming tooling, cold forging, cold forging, hot forging tools and die components for aerospace applications from drawings.

Cold forging, hot forging, cold heading and molding dies in the aerospace field.

Related products

Automotive Tungsten Carbide Custom Tooling Macining

Automotive Technology

We help keep the automotive industry alive.

New innovations, changing products and customer demands have made flexibility and adaptability part of manufacturing in the automotive industry, as has the production of tools and dies used in the automotive market. The tools and mold solutions produced need to be flexible, precise and durable to withstand the rigors of automotive manufacturing and create a significant return on investment to help you stay competitive.

SPP CARBIDE offers tool manufacturing services in a wide range of materials such as tungsten carbide, technical ceramics, steel, aluminum alloys, etc., which are perfectly suited to meet the custom tooling machining requirements of the automotive and new energy vehicle sectors.Hot & Cold Forming Trimming Dies & Inserts

We offer precision tooling making for the cold & hot forging sector, they are generally made of carbide, M42, M2, HSS, 1.3343, ASP60 and others.

Hot & Cold Forming Dies & Inserts

Die Assembly

Steel Inserts

Carbide Inserts

Segmented Carbide Inserts

Replaceable Carbide Inserts

Trimming Dies

Open Dies

Die Screws

Die Fillers

Serration Heading Dies

Die Sleeves

Pointing Dies

Die Fillers

and more.Special Shaped Cold Forming Punches & Tooling

Cold heading extrusion punches

Cold heading is the process of feeding wire into a machine that cuts it into pieces and then hammers it. The material is not heated or processed, but formed into the desired shape at room temperature. The ability to form the material rather than remove it makes the process extremely efficient and cost effective in high volume production.We design and manufacture our own custom tooling and make virtually all fastener forms, including multiple upsetting configurations, custom head shapes and replacements for multi-part assemblies. Transforming your supply requirements to cold heading can benefit in many ways.

Hot & Cold Forming Punches & Pins

Forming tools

We manufacture customer designed punches, dies and auxiliary tools using a wide range of carbides and steels to provide the ultimate solution for maintaining high performance.

Our advantages: 1: Reduced production costs, by maintaining efficiency and reducing downtime. 2: Improved product performance, through heat treatment and various PVD coatings to extend tool life. 3: High precision, state-of-the-art CNC machining to form complex shapes for multi-stage upsets.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.