Semiconductor MGP Mold Die Machining

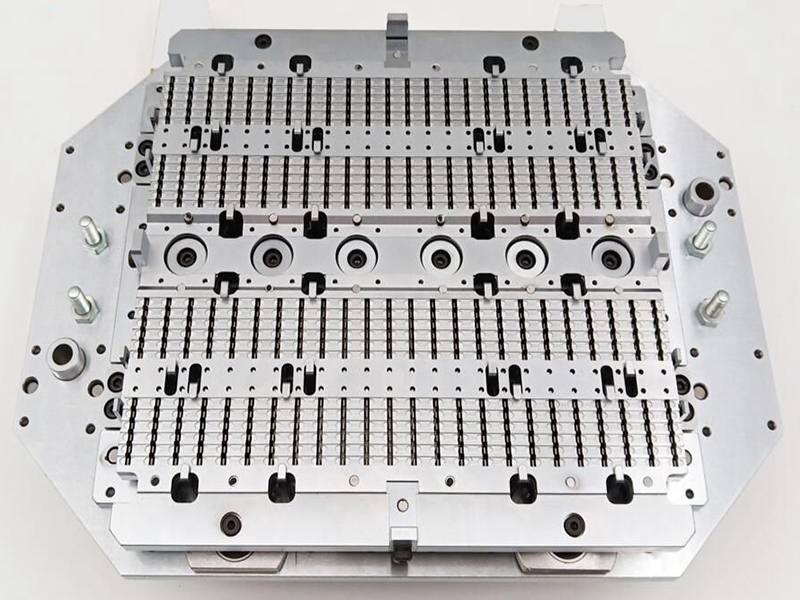

Application: Mainly used for post-process packaging of integrated circuits and semiconductor devices.

Features: Multiple cans and plungers. Implementation of short filling distances.

Advantages: good plastic sealing process, packaging quality improvement; mould box with quick-change structure, easy to use and maintain.

Applicable package types:

1. QFP, LQFP, TSOP, PLCC, SOT, SOD series;

2. Matrix SOP, SSOP, TSSOP series;

3. SMD tantalum, SMD sensing and DIP, TO, etc. with high requirements;

4.DIP and SDIP series

Application: mainly used for post-process packaging of integrated circuits and semiconductor devices.

Features: Multi-can and multi-plunger. Implementation of short filling distances.

Advantages: good plastic sealing process, packaging quality improvement; mould box with quick-change structure, easy to use and maintain.

-. Balanced filling and high quality

-. Quick-change moulded parts

-. Fast curing compounds use

-. Suitable for all types of packaging

-. Solutions for venting and gate design to ensure good moulding

performance (voids, swept lines and incomplete filling).

-. Minimising the use of compounds

-. Individual chasing X-Y positioners on the top and bottom four sides

-. Standard material: ASP23

-. Pot and plunger head: T.C

-. Chase interlock design: Misalignment <1.5

-. T.C Gate insertion design

-. E-J pins without crown flash

-. Heat loss cover: Teflon cloth (blanket) / DuPont Nomex - T994

For semiconductor manufacturing

Related products

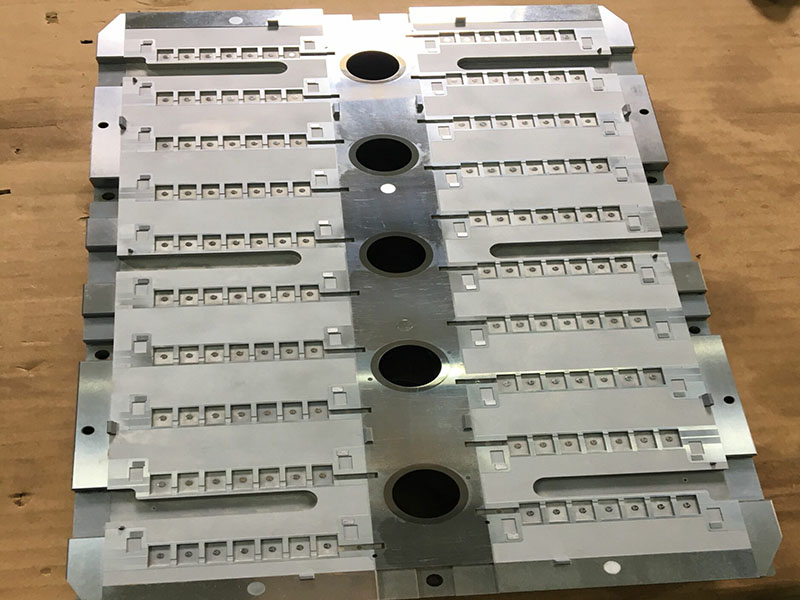

IC Packaging Mold Cavity Bar and Auto Mold Chase

Application: Suitable for TOWA, FICO, ASM, HANMI brand AUTO MOLD SYSTEM

Can be used in conjunction with automatic encapsulation systems to improve the intrinsic quality of the product.Semiconductor Tooling Manufacturer

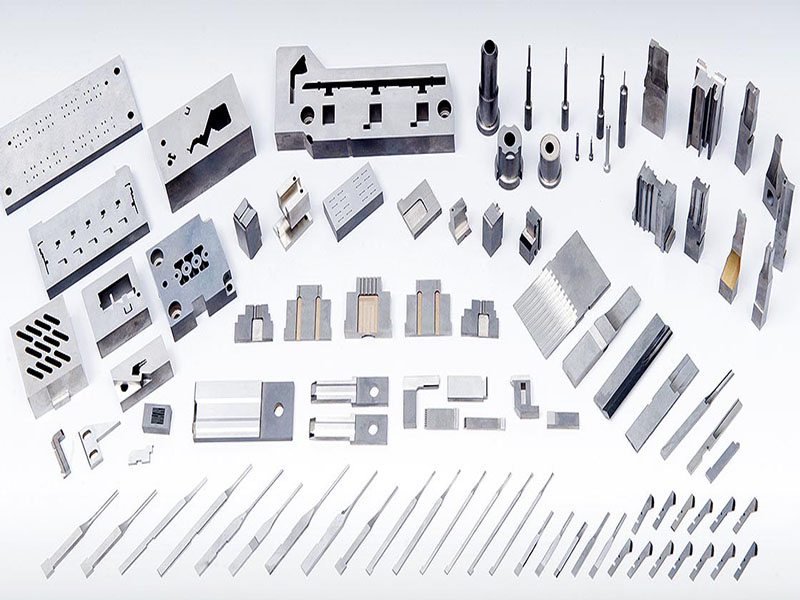

The semiconductor tooling industry is one of our key markets. We have extensive experience in manufacturing tools for the back-end semiconductor industry, semiconductor packaging, semiconductor leadframes and more. From modules and fixtures for chip attachment to conversion kits for IC test processors to ceramic arms for wafer handling and package and leadframe die components, we have the skills and expertise to build your product to your exacting standards.

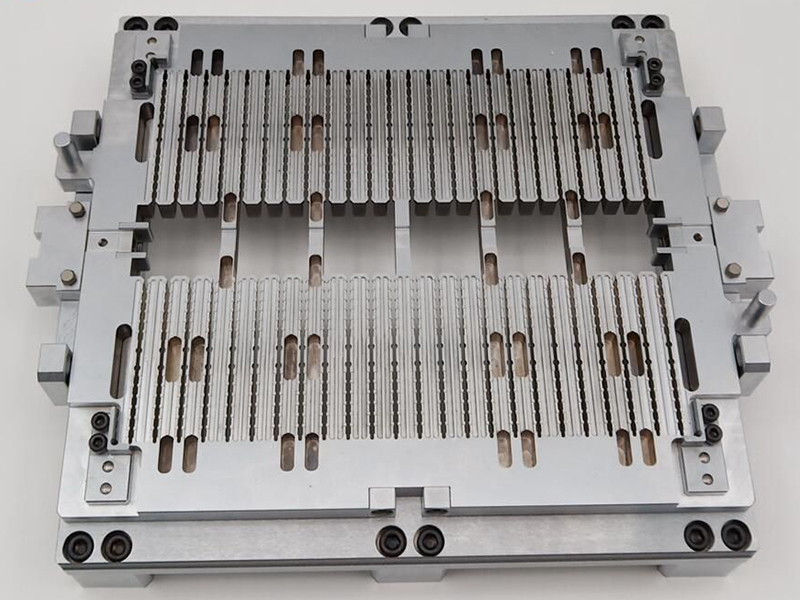

Custom Machining Pot & Plunger for Semiconductor Packaging

The company is one of the largest manufacturers of Pot & Plunger in China and we provide OEM services for Pot & Plunger to well-known semiconductor companies in China and Taiwan.

Pot & Plunger is used in the manufacture of semiconductor packaging moulds. The company's Pot & Plunger can be manufactured using M42 high speed steel or tungsten carbide and can also be supplied with additional PVD coating services.Semiconductor Leadframe Mould & Die Tooling Machining

Semiconductor leadframe moulding A metal substrate that serves as a lead to connect a semiconductor chip to external circuitry and as a frame to hold a semiconductor package to a circuit board.

As a key component of a semiconductor integrated circuit, it is connected to the chip by thin leads and transmits electrical signals between the semiconductor chip and the substrate, and acts as a frame to protect and support the chip from external moisture or shocks.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.