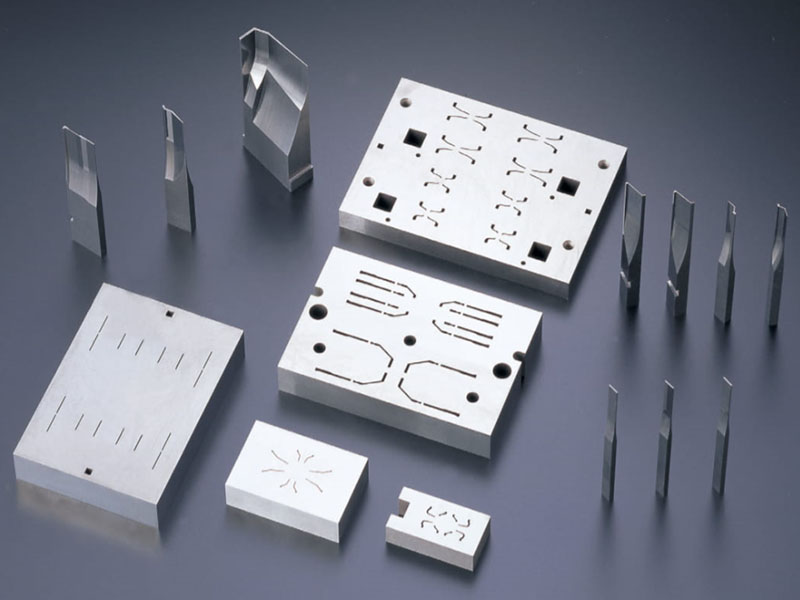

OEM/ODM Punches and IC Die Pins for Semiconductors

Precision stamping die components are used in the semiconductor field. Punches and IC die pins are finished with tungsten carbide or hardened tool steel, and additional PVD coating services are also available. SPP INDUSTRY's die components are 6 times more durable than ordinary die standard parts, which is one of our patented products.

Manufacture of semiconductor tools and components according to drawings:

-IC mold pins

-POT, PLUNGER

-GATE INSERT

-Cavities and inserts

-Hot runner parts

-CORE & MICROPIN

-Technical Ceramic Wafer Handlers

-Silicon carbide wafers, etc.

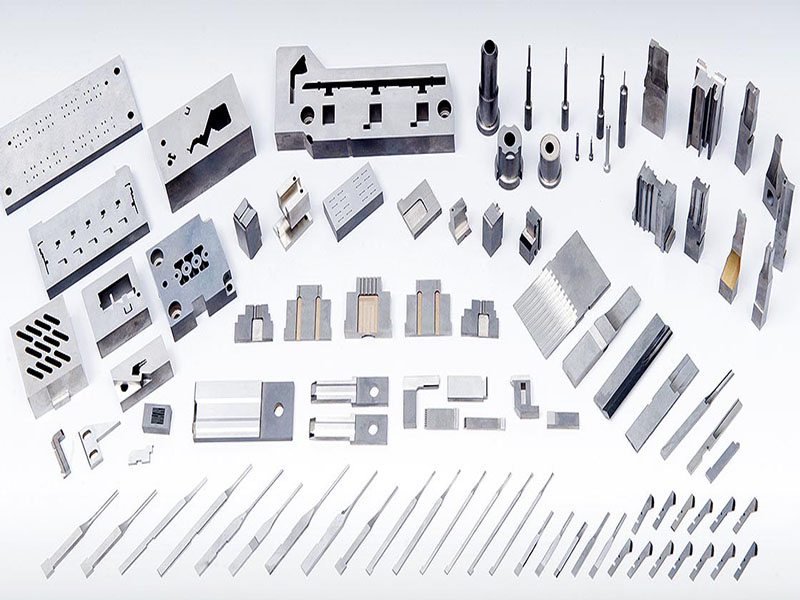

Precision semiconductor component OEM services

Applications and Semiconductor Industry:

-IC

-Semiconductor tools and dies

-Leadframe stamping tooling

-Semiconductor packaging tooling

-Wafer fabrication, etc.

Related products

Semiconductor Components and Tooling Manufacturer

We are a manufacturer of semiconductor components and tooling, providing high precision OEM parts services, including tungsten carbide punches, package mold cartridges and plungers, leadframe stamping mold parts, IC hot runner gate parts, etc.

Semiconductor Tooling Manufacturer

The semiconductor tooling industry is one of our key markets. We have extensive experience in manufacturing tools for the back-end semiconductor industry, semiconductor packaging, semiconductor leadframes and more. From modules and fixtures for chip attachment to conversion kits for IC test processors to ceramic arms for wafer handling and package and leadframe die components, we have the skills and expertise to build your product to your exacting standards.

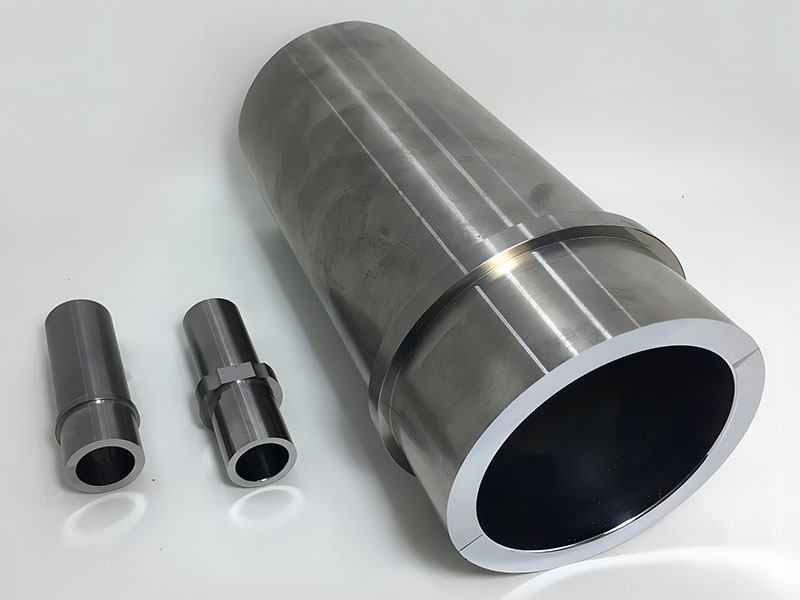

Semiconductor Pot & Carbide Plunger Manufacturers

The company is a manufacturer of the semiconductor Pot & Plunger, which is finished in tungsten carbide and is manufactured and customised according to drawings

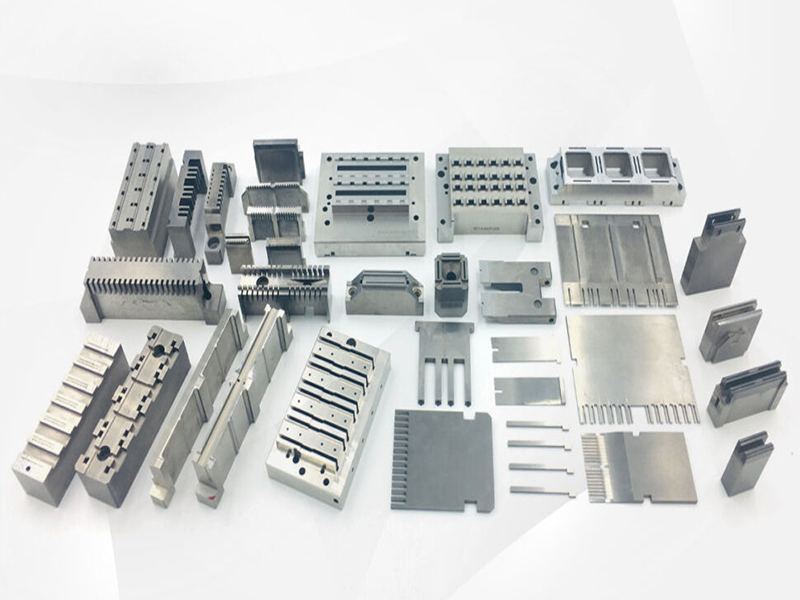

Semiconductor Leadframe Mould & Die Tooling Machining

Semiconductor leadframe moulding A metal substrate that serves as a lead to connect a semiconductor chip to external circuitry and as a frame to hold a semiconductor package to a circuit board.

As a key component of a semiconductor integrated circuit, it is connected to the chip by thin leads and transmits electrical signals between the semiconductor chip and the substrate, and acts as a frame to protect and support the chip from external moisture or shocks.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.